Gearboxes are key parts in vehicles, machines, and industrial gear. They help transfer power from the engine to the wheels or other moving parts. But like any machine, gearboxes can have issues that need repair. In this article, we will explore common gearbox problems, their causes, and how to repair them. Whether you’re a car owner, mechanic, or someone interested in machinery, this guide will help you understand gearbox issues better.

What is a Gearbox?

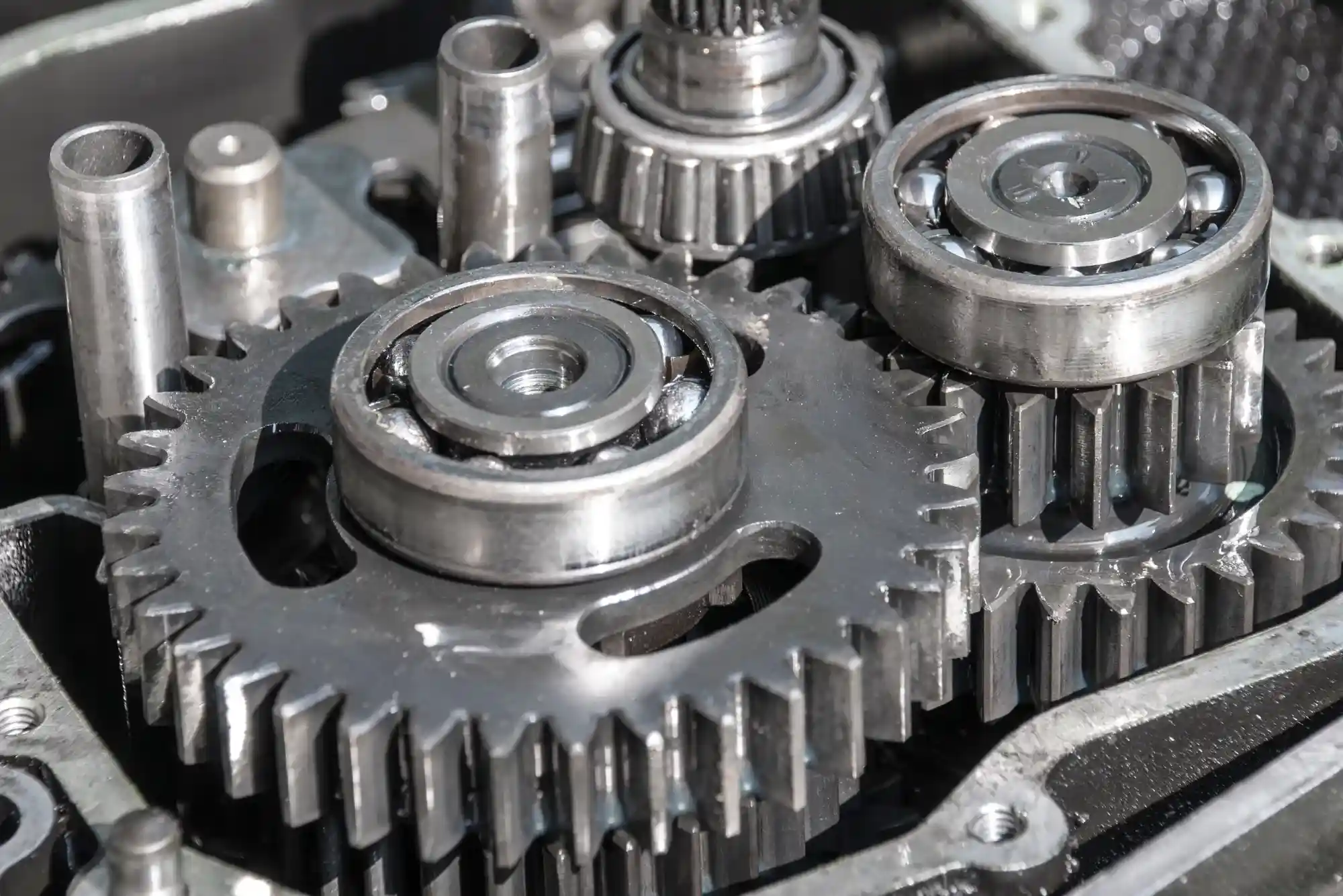

A gearbox is a mechanical device that helps control the speed and torque of a machine. It works by adjusting the rotational force from the engine to match the needs of the task. For example, in cars, the gearbox allows drivers to shift gears smoothly for acceleration or climbing hills. Without a properly functioning gearbox, machines and vehicles cannot operate efficiently.

Common Gearbox Problems

1. Leaking Oil

One of the most frequent gearbox issues is oil leakage. This happens when seals or gaskets wear out, causing lubricant to escape. Without enough oil, the gearbox can overheat, leading to further damage. Signs of oil leaks include puddles under the vehicle or a burning smell while driving.

Solution: Replace worn-out seals and gaskets. Regular maintenance, such as checking oil levels, can prevent this issue.

2. Strange Noises

If your gearbox makes grinding, whining, or clunking sounds, it may indicate internal damage. These noises often occur due to worn-out gears, low oil levels, or misaligned components.

Solution: Inspect the gearbox for damaged parts. Replacing faulty gears or refilling oil can solve the problem. If the issue persists, consult a professional mechanic.

3. Difficulty Shifting Gears

Shifting gears should feel smooth and effortless. If you notice stiffness or resistance, it could be due to a malfunctioning clutch, low transmission fluid, or internal damage.

Solution: Check the clutch system and ensure the transmission fluid is at the correct level. In severe cases, repairing or replacing the gearbox may be necessary.

4. Overheating

Gearboxes can overheat if they lack proper lubrication or ventilation. Overheating may also result from excessive load or prolonged use. An overheated gearbox can lead to costly repairs if not addressed promptly.

Solution: Ensure the gearbox has adequate oil and cooling systems. Avoid overloading the machine or vehicle.

5. Vibration or Shuddering

Excessive vibration while driving or operating machinery can signal gearbox trouble. This issue often arises from misaligned components, worn-out bearings, or damaged mounts.

Solution: Inspect and realign the gearbox. Replace damaged bearings or mounts to restore smooth operation.

6. Slipping Gears

When gears slip out of place during operation, it disrupts performance and can be dangerous. This problem is often caused by worn-out synchronizers or improper adjustments.

Solution: Repair or replace the synchronizers. A qualified technician can fine-tune the gearbox to prevent slipping.

Causes of Gearbox Problems

Understanding the root cause of gearbox issues can help prevent them. Here are some common causes:

- Lack of Maintenance: Failing to check oil levels or replace worn parts can lead to serious problems.

- Wear and Tear: Over time, gears and components naturally degrade due to constant use.

- Improper Use: Overloading the gearbox or using it incorrectly can cause damage.

- Poor Quality Parts: Using low-quality components during repairs can lead to early failure.

- Environmental Factors: Exposure to extreme temperatures or contaminants like dirt and water can harm the gearbox.

How to Maintain Your Gearbox

Regular maintenance is key to avoiding costly repairs. Here are some tips to keep your gearbox in good condition:

- Check Oil Levels Regularly: Ensure the gearbox has enough lubricant to function smoothly.

- Inspect for Leaks: Look for signs of oil leaks and fix them immediately.

- Follow Manufacturer Guidelines: Adhere to the recommended service schedule for your vehicle or machine.

- Use Quality Parts: Always opt for high-quality components during repairs.

- Avoid Overloading: Operate the gearbox within its designed capacity to prevent strain.

When to Seek Professional Help

While minor issues can be fixed at home, some problems require expert intervention. If you notice persistent symptoms like strange noises, difficulty shifting gears, or overheating, consult a professional mechanic. Skilled technicians have the tools and expertise to diagnose and repair complex gearbox issues.

For those dealing with advanced machinery, seeking help from specialists familiar with Germanic engineering standards can be beneficial. Germanic engineering is renowned for its precision and reliability, making it a trusted choice for gearbox repairs.

Conclusion

Gearboxes are vital for the smooth operation of vehicles and machinery. By understanding common issues like oil leaks, strange noises, and difficulty shifting gears, you can take proactive steps to maintain your gearbox. Regular maintenance, proper use, and timely repairs can extend the lifespan of your gearbox and save you money in the long run.